Geosynthetics Concrete Mattress for Erosion & Scour Protection

When constructed, the Concrete Armor Mattress provides many superior technical advantages for erosion control and scour protection.

Some of the outstanding qualities are his Hydraulic Stability and Trouble to wear.

It is designed to resist the high flow velocities and wave action that would displace loose rock (riprap). The high mass of the individual blocks gives resistance to lift and drag forces and the open area (typical range of 8–20%) also facilitates the velocity reduction of surface runoff and vegetation growth, which together further increase stability.

Inherent Flexibility and Conformability

The articulated design enable the mattress to flex and contour with the subgrade, unlike stiff concrete slabs. It is able to bridge small gaps and follow complex profiles (i.e. channel bends, culvert outlets and pipeline crossings) without cracking which is a major failure mode of cast-in-place concrete.

Superior Filtration and Soil Retention

The first line of defense for this system is the integral geotextile underlay. It acts as the dual role of filter fabric to prevent fines being pumped out via the mattress joints and a separator to prevent loss of subgrade integrity which is the leading cause of revetment failure.

High Permeability and Drainage

Open joints between the blocks and permeable geotextile [1] allow for quick draining groundwater. It stops hydrostatic pressure from building under the mattress, which is a cause of failure in impermeable systems.

Durability and Long Design Life

Made from weather-resistant concrete and UV-stabilized geosynthetics, the system provides a design life greater than 50 years. Freeze thaw, chemical attack resistant in most environments & biologically resistant.

A New Engineered Armor Solution — Geosynthetics Concrete Mattress (GCM) for Critical Erosion and Scour Protection

Article Overview: Things to Know About Next-Gen Hydraulic Structure Protection

Erosion and scour are adversaries that we wage a continual struggle against in the hyper-demanding arenas of hydraulic engineering, marine construction, and infrastructure protection. Conventional methods such as rock riprap or poured-in-place concrete tend to have issues with durability, flexibility, installation time, and environmental impact. An engineered solution that offers a breakthrough in design principles and overcomes these limitations is the Geosynthetics Concrete Mattress (GCM), also known as Concrete Fabric Mattress (CFM) or Articulated Concrete Block (ACB) System. A high-performance monoculture armor layer, this innovative and versatile system combines both the mass and erosion resistance characteristics of concrete with the geosynthetic property of filtration and containment to yield a fully integrated modular flexible revetment system. With the Geosynthetics Concrete Mattress being so advanced, international B2B buyers working on waterways, coastal, energy, and transportation projects all need to know how to appropriately specify a long-lasting, economical, and environmental protection system.

PRODUCT OVERVIEW: A Modular Composite Solution With Flexibility

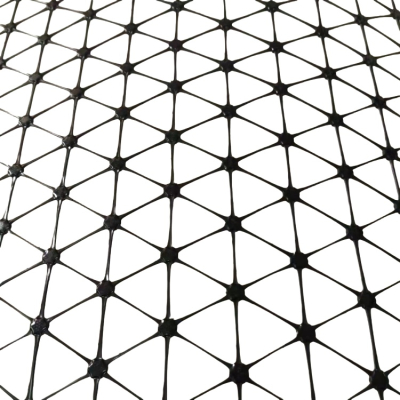

A Geosynthetics Concrete Mattress (GCM) is a prefabricated, flexible mattress made of discrete concrete blocks linked by high-strength polymeric geogrids or cables, and supported by a non-woven geotextile filter fabric. Such are the benefits of an integrated design, forming a system which is truly so much greater than the sum of its individual parts.

Core Components and Construction:

2Concrete Blocks/Units: These are high-strength concrete blocks (usually hexagonal, square, or rectangular in a size of 40 cm or more) either cemented on site or factory-casted. They are designed for particular hydraulic loads in terms of their size, thickness (usually 75mm to 200mm) and percentage of open area.

Polymeric Matrix/Grid: The blocks are hinged together via openings, with this connection formed by a network of high tenacity polyester or polypropylene geogrids or cables. This results in a continuous, flexible, hinged blanket of concrete capable of conforming to subgrade irregularities without compromising structural integrity.

Geotextile Filter Layer: This option features a needle-punched, non-woven geotextile with a very high strength which is either integrally bonded or mechanically attached to the bottom of the block matrix. It is essential to convey that this key element serves as a filter to both minimize soil loss from the underlying subgrade, and at the same time help dissipate pore water pressure and effectively eliminate hydrostatic uplift forces.

Edge and joint details: Systems provide for specialized edge units and connectors to maintain continuity of the mattress panels and with an adjacent structure (numerous types such as abutments or sheet piles).

Manufacturing Excellence:

GCM is produced in factory conditions where stringent quality control measures are enforced. It is a method that includes accurate casting of concrete units, assembly with geogrids that are stabilized against UV light, and also lamination or addition of the filter cloth. It guarantees the quality of the product, physical dimensions, and performance, all of which are better than site-built variation.

Primary Application Areas

For high-consequence applications, where failure is not an option, the appropriate solution is Flexible Concrete Mattress.

Waterway and Channel Protection

APPLICATION: For the Lining of drianage channel, Floodways, riverbank & cutslopes of canals

Advantage: Durable, low maintenance, and hydraulically efficient scour-countermeasure for high-velocity flows of long duration. It has a core application for erosion control mattress.

Coastal and Marine Defense

· use: Revetments for shoreline protection, dune core armoring, and cover layers for breakwaters

· Advantage: Resists wave run-up, reflection and scour at the toe of structures It is also flexible enough for some settlement to occur without reduction of protection.

Infrastructure Scour Protection

Applications: At abutments & piers to protect against bridge scour; Pipe & utility crossing protection (e.g., subsea pipeline mattress); Outfall structures

· Value: Avoids systemic undermining of key infrastructure. One of the key benefits is its ability to be custom fitted around complex shapes, unlike riprap.

Hydraulic Structure Energy Dissipation

· Use: Liners for spillway chutes, stilling basins, dam overflows, and culvert outfalls.

Benefit: Arrives to guard the underlying soil structure from the extreme turbulence and abrasive forces of the high velocity, aerated flows associated with the gully.

Slope Stabilization and Landfill Closures

· Uses: Counter cover for final caps over landfills and stabilization of steep slopes that are vulnerable to erosion.

· Value: Carries a stable, vegetated layer that absorbs stormwater runoff and prevents the erosion of covering soil.

Installation Process Overview:

Subgrade Preparation: The site is graded to design contours and compacted. Smooth, no sharp objects on the surface

Mattress Installation: Prefabricated mattress panels (usually 30m in length and up to 35m in width) are rolled out or lifted into position with light machinery. Integral loops or cables connect adjacent panels.

Arc and End: The upper, lower, and side beards are braced in the anchor trenches and stored with concrete or with compressed dirt. Mastic seals or backfill compatible with the filter are used to connect to structures.

Weighted Final Grade: The installed mattress is lightly tensioned to ensure full contact with the subgrade.

Question 01: What is the cost-effectiveness and performance of a Geosynthetics Concrete Mattress versus traditional rock riprap?

A: The GCM system has a better total installed cost and is a greater long-term value despite possible higher initial material costs. Differentiators would be: Fast to install with lower crew and equipment requirements, higher allowable flow velocities (steeper channel slopes etc = land savings), no additional filter layer needed and many magnitudes lower long-term maintenance as a monolithic, non-displaceable, product. Its performance is also more deterministic and subject to engineering-style verification.

Q2: Does vegetation come through the mattress, and is that a good thing?

A: Is it advisable though? And, is it even physically beneficial? The void ratio between the blocks are left open such that soil can be filled and vegetation can grow throughout. Soil stabilization of the underlying soil through root anchoring although root anchoring has a positive impact, it also acts as the secondary stabilization, which increases the esthetic value of the system encouraging ecological harmony. It turns it into a green engineering solution for the structure.

Q3: When selecting the appropriate mattress for a high-velocity channel application, what are your key design parameters?

A: Engineering design must be part of this process, and it should take into account:

· Block Width & density: In order to counter the computed shear stress and lift forces

· Open Space Ratio: Hydraulic performance vs soil retention and the potential to support vegetation

· Filtering Mechanism of Geotextiles: The apparent opening size (AOS) and permittivity should be coupled with the gradation of the subgrade soil to prevent piping but to promote drainage.

· Flexibility of the System: Type and rigidity of the interconnecting grid must accommodate for expected subgrade settling. Reliable manufacturers mention that they provide design software and engineering support.

Q4: Can these mattresses be permanently submerged in saltwater?

A: Sure, but the specifications need to be adapted for maritime applications. This requires:

· Marine Accessible Concrete: Low Permeable Concrete & good cement mixes resistant to sulfate damage to sea water.

· HP Geosynthetics: Hydrolysis Resistant polyester geogrids and marine organism abrasion resistant geotextiles.

· Installation: Security for connections and working on the details ensuring all edges can handle the tidal force and impacts of any elements that might float onto the infill so we can chuck on a concrete seal. They are an established answer for erosion protection under the sea.