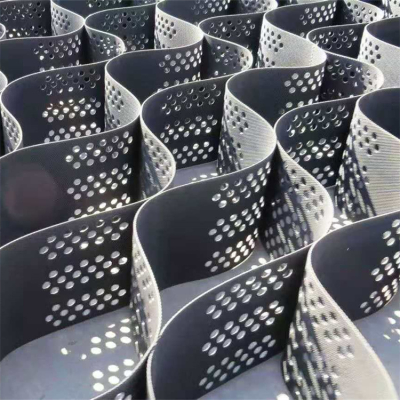

Geotube Dewatering Bags

A Geotube is not simply a geotextile fabric bag; in fact, it is a properly engineered system where its behavior is directly influenced by the geotextile properties, the geometry of the system and method of deployment.

Core Component: The Engineered Geotextile

The tube itself is made of high strength woven polypropylene geotextile. This material is the perfect choice, and is custom designed for:

· Controlled Permeability- The fabric´s exact apparent opening size (AOS) permits water to flow out while retaining the fine solid material effectively. It is this equilibrium which is important for the rapid dewatering and solids capture.

· Very High Tensile Strength: The woven construction offers superior seam strength and birst resistance to counter the tremendous hydraulic and static forces generated by liquid and solid content when the bag is full.

· Durability and UV Resistance: Fabric is treated for maximum UV exposure life when used in the dewatering process that can take weeks or months.

· Anti-Clog Feature: The mesh withstands blinding, allowing good drainage even when fine grained silt and clay products are used.

Geotube Dewatering Technology The Sustainable Solution For Sediment and Sludge Management

INTRODUCTION: LARGESCALE DEWATERING AND CONTAINMENT REVISITED

In tackling these global problems of environmental cleaning, coastal defence and industrial waste management, objectives are efficiency, cost-effectiveness and engineering compliance. Geotube technology has delivered a new and powerful tool for the dewatering of shoreline material in an efficient, environmentally friendly, and cost-effective manner. A Geotube container is a large geotextile bag used for dewatering and sludge removal on large volumes in the environmental industry. The sludge is pumped into these specially woven cloth boxes, and water drains to the outside leaving that much less volume in a lagoon to dispose of or process further. B2B buyers from all over the world in dredging applications, mining, wastewater treatment or fish farming are some of those who benefit most from mastering the Geotube dewatering technology to get more out of their project budget and still comply with strict environmental regulations.

.

System Components and Design

A Geotube dewatering system typically comprises:

Geotube Unit: Tailor-made to given dimensional sizes (circumference and length). Typical circumferences are 10 to over 100 feet; lengths frequently exceed 100 feet.

Filling Openings: Molded inlets, reinforced, integrated Throughout the length of the tube for connection to distributor pipes.

Pumping and Mixing System Slurry is transferred using high volume pumps. Polymer flocculants are commonly added to the feed stream to agglomerate fine particles which significantly increases the dewatering efficiency and clarity of the effluent.

Containment Area: A design well or area in which tubes are set and that has been prepared, frequently lined with an impermeable geomembrane, to contain any accidental release.

Technical Characteristics & Performance Advantages

There are several mechanical, economic and environmental advantages in applying Geotube technology.

High-Efficiency Dewatering and Volume Reduction

This is the core function. Geotube dewatering is capable of reducing sludge volumes by 50 to 90% through the use of in situ separation of water from solids. This translates directly into:

· Substantially reduced cost of transport to final disposal or beneficial use.

·Drying beds storage compacted footprint.

· More rapid project closure than traditional lagoon drying phase.

Effective Solids Containment and Stabilization

The geotextile functions both as a filter and as a strong container which can immobilize the pollutants (e.g., heavy metals or organic contaminants) in an easily manageable, solid form. The liquid sludge is dewatered, and the process effectively converts a liquid-containing problem into manage- ment of solid waste.

Adaptability to Diverse Materials

Geotube Containers Work for a Diverse Amount of Materials:

· Sediments dredged including sand silt clay

· Industrial sludge (mineral treatment, power plants, pulp and paper)

· Agricultural waste (animal manure, lagoon sludge)

· Algae and sludge from water sources

· Water treatment residuals

Cost-Effectiveness and Operational Simplicity

Infrastructure needed for the system is relatively basic, including a specified location, pumps, and polymer feed equipment. It removes the necessity for wasteful and costly mechanical dewatering presses, centrifuges, or enormous lined drying basins. The per cubic meter dewatering cost is often much below that for mechanical means.

Environmental and Safety Benefits

· Reduces Odor and Vector Attraction: by suipl,» drying of liquid waste.

· Escort Leachate Migration: Contained, dewatered solids have lower potential for contaminant control.

· Supports beneficial reuse: Dewatered, clean sediments can be used as a landform, cover material or construction fill.

Primary Application Areas

Geotube technology is now employed as a “first line of defense” in many environmental and containment applications.

Dredging and Marine Works

· Application: Dredge clean or contaminated sediments for harbor, river and canal maintenance dredging.

· Benefit: Dewatering technology simplifies confined aquatic disposal or for placing dewatered material on uplands — transforming dredge spoil, previously viewed as waste. This is a top application for sediment dewatering.

Environmental Remediation

· Use: Sludge with a passing effect from contaminated basins, ponds and industrial premises.

· Advantages: safely holds heavy metals and toxins, aiding in site clean up / decreasing liability.

Mining and Mineral Processing

· Industry: Tailings and process water sludges.

· Advantages: Recovers water for processing re-use and creates a dense, stackable solid product in a stable form of dry-stack tailings management—a greener, safer alternative to slurry-type storage facilities.

Aquaculture and Agriculture

· Application: Deslagging of pond sludge of shrimp, fish or any other ponds.

· Use dry: Reclaiming nutrients in a solid and can be used as fertilizer while improving pond water quality.

Shoreline and Erosion Protection

Application: A Geotube unit filled with sand or soil is a subaqueous breakwater, groyne (or groin), or dune core revetment.

· Advantages: A robust, flexible and economical solution for coast protection, wave absorption.

Installation and Operation Process:

Site Preparation: The area is levelled and stabilised, commonly with a protective base layer and edge bund.

Tubes Deployment: the void tubes are floating and anchored.

Slurry conditioning and filling: Conditioned slurry is floc-culated in the tanks, then pumped to the tubes via filling ports. Fill is placed in layers, and the fill must be allowed to drain and consolidate between increments.

Dewatering and Consolidation – Water passes easily through the geotextile, leaving solids to dewater. This phase may last several weeks.

Closure and Disposal: Tubes are sliced open after dewatering is completed and the solid cake is hauled offsite for disposal, capping a landfill or beneficial reuse.

FAQ for Foreign Purchasers and Project Engineers

Q1: What is the common dewatering time period for a Geotube unit, and what are the factors that affect it?

A: The dewated time depends on the characteristics of the slurry (grain size, initial solid content) and conditions. Coarse-grained sand could dewater in days, whereas fine clay slurries could take weeks to months. The trick to speeding the process is efficient polymer coagulation which forms bigger particle masses that drain away with greater ease. Ambient temperature and evaporation rate are factors as well.

Q2 How do you determine correct geotextile filter fabric properties AOS for a slurry?

A: That would take some expert engineering. The AOS of the geotextile shall be small enough to prevent passage of the intended size particle, yet large enough to permit rapid over flow of wate r without clogging. Retention testing is conducted by the manufacturers with slurry samples from a particular location to recommend the appropriate fabric grade. The use of too tight a fabric may impede drainage; too open a fabric can lead to the release of fines.

Q3: Can the effluent discharging from Geotubedewatering be directly discharged to environment?

The clarity of the effluent will vary depending on how well floculates and retention in the fabric. For environmentally sensitive projects, the effluent can be collected in a sump, sample tested and recirculated and/or treated prior to being discharged. Engineered, polymer-feed systems can generate extremely clean effluent, which may be discharged directly to receivers or recycled.

Q4: How long will the belt last for dewatering A: It is a single use fabric and can serve from a period ranging several months to a few years, but this depends on the product type. If used as a long-term or permanent structure (i.e., for shoreline protection), the tubes will be typically specified with high UV stabilized geotextiles, and must be covered with sand, rock, or other materials to provide natural stability and a longer lasting life; guidance exists on measures to prevent damage by ultraviolet light. Geotextile Type The type of geotextile used must be appropriate for the durability requirements of any given project.